On our way to sustainable

development..

Valmont is gradually implementing a CSR (Corporate Social Responsibility) approach that integrates the three components of sustainable development while committing to developing a continuous improvement process via a QSE (Quality, Safety, Environment) policy.

Economy

With the acquisition of its first subsidiaries in 1989, the group advocates local production for local consumption.

Thus 95% of the products manufactured in Europe are distributed on this territory.

The same goes for its North American market as well as for its Asian market.

With its subcontractors, the group’s entities set up contracts that take into account the partner’s capacity without endangering its overall business .

Social

The employees of the various subsidiaries as well as management staff are recruited locally

The management of the companies respects local social laws as well as international human rights law. For this reason, child labor is not tolerated in our production units.

Each production unit conducts :

- A training policy accessible to all its employees.

- A policy of Continuous Improvement, the Valmont Way. It allows each employee to contribute to the Optimization of his position in terms of Ergonomics, Organization or Procedures.

Environmental

The points of progress are visible throughout the life cycle of its products, from the extraction of raw materials to the recycling of products at the end of their lifecycle .

Supply

25%

of the Steel comes from Recycled Steel

30%

of the Aluminum comes from recycled Aluminum

100%

The wood comes from sustainably managed forests that are PEF certified.C

Conception

Use of High Elastic Limit Steel in production in order to optimize the quantities of material required for a given use.

Systematic optimization of the quantities of materials necessary for the elaboration of a product, in compliance with the calculation standards in force.

Production

- The Charmeil Powder Coating line has “0” environmental impact.

- The wood production site in Parikkala is 100% heated with its waste and production scraps.

- The Aluminium de Rive de Gier and Acier de Charmeil production sites recycle 100% of their scrap and production waste.

- The Aluminum from Rive de Gier and Steel from Charmeil production sites are ISO 14001 certified.

- The delivery of the products is organized in rounds in order to optimize the transport and thus reduce its impact.

end of life

Valmont undertakes on simple request to take back the masts. Returns organized within the framework of delivery rounds…

Eco-responsability

Our objective is also to obtain the lowest possible carbon footprint of your projects, all materials included… Valmont is already able to provide the CO² footprint of each of its products.

Compensation

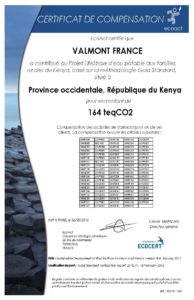

ZEP – Zero Emission Pole

Once the carbon footprint has been evaluated, Valmont France offers its customers the option of opting for a CO2 neutralization approach with the choice of offsetting.

To do this, Valmont France has teamed up with a carbon offsetting organization that offers missions. The goal is to balance the impact of a project by carrying out actions based on social, environmental and/or economic criteria.

The neutralization of greenhouse gases requires financial support for these development aid programs. These funds are used for several missions in 19 countries.

Under the PTA program, a percentage proportional to the carbon footprint of the product sold is levied (upon request) on the sale of each pole and remitted to this organization. In return, an official certificate is given to the project owner attesting to its environmental commitment.

Our partener: www.eco-act.com